We specialize in the design, manufacturing and installation of custom electrical switchboards, both suited for energy supply and control and for automation of any kind of industrial installations and manufacturing processes. We also stand in a leading position in automated electrical manufacturing for the railway sector.

We are part of ELEKTRA GROUP, which have been a major reference in the electrical equipment market for more than 40 years. Our common goal: providing the highest levels of quality and reliability to our customers.

Sectors

Railway

By combining our experience with the most innovative processes of harnessing and switchboards integration, we’re able to offer you the best manufacturing techniques in the railway sector. We use automation in order to reach the highest level of precision and reliability in the cutting, labeling and wiring process.

Energy

In order to improve the power efficiency of our client’s installation, as well as offering the highest levels of security and reliability, we always pay a deep attention to this kind of projects.

Our fully integrated systems are based on the most advanced technology, which allows us to provide complete solutions of both energy production and energy conveying.

We keep

on innovation

Services

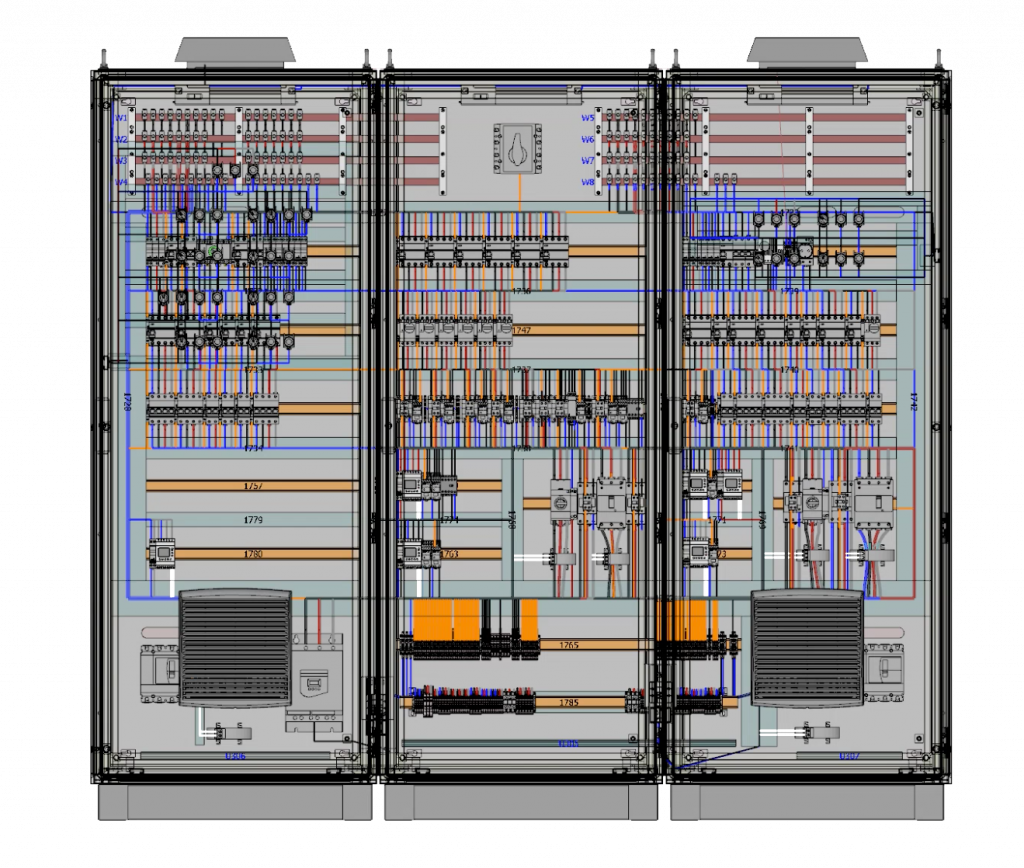

Engineering design with Eplan

The initial phase of our projects consists in our engineers developing a multi-line diagram, which includes a precise template of all the connections needed, as well as information about the wires with their particular colour and length, in order to proceed with the automated routing simulation.

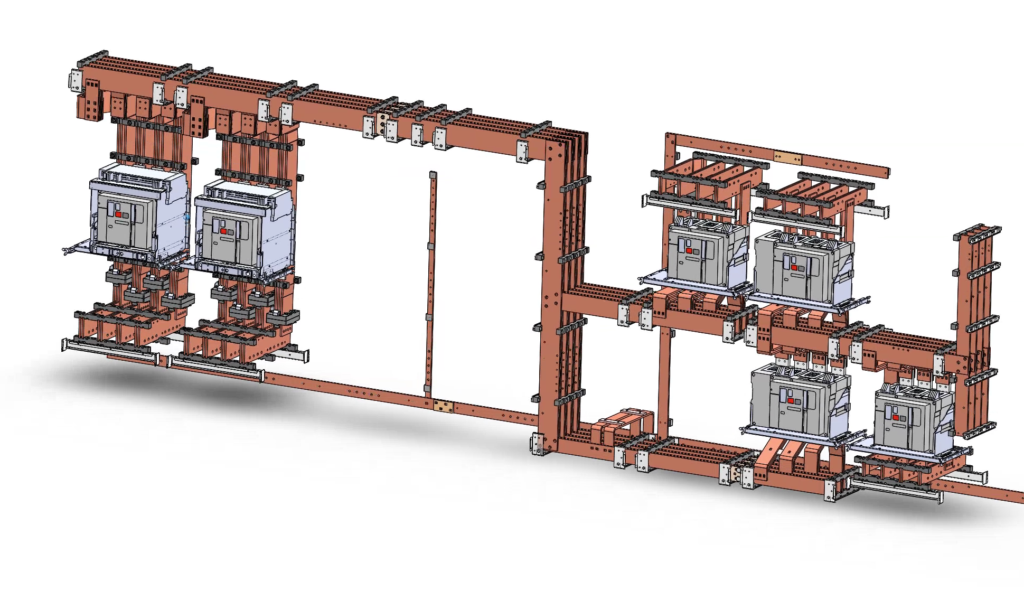

Engineering design with Solidworks

Our dedicated SOLIDWORKS platform allows us to design complex busbar systems, for electrical panels up to 6300 amperes, and to carry out their automated manufacturing, which includes several operations like cutting, punching, threading and bending of the copper bars, either bright or tinned.

News

A highly complex project made up of 116 electrical panels was manufactured by Kuadrotek

We have manufactured a highly complex project that has not been completely industrialized by our client, which for us achieves a milestone to improve and

One of the great projects that we have manufactured has been launched in service

We manufactured electrical panels for a project for two subway lines, including the integration of the interconnections. The manufacturing was made in parallel and each subway

Commitment to daily improvement

Every step of our manufacturing processes gets regularly checked, evaluated, and often improved on a technical level, in order to guarantee the highest quality of our products and to comply with international standards.